News

27.05.2025

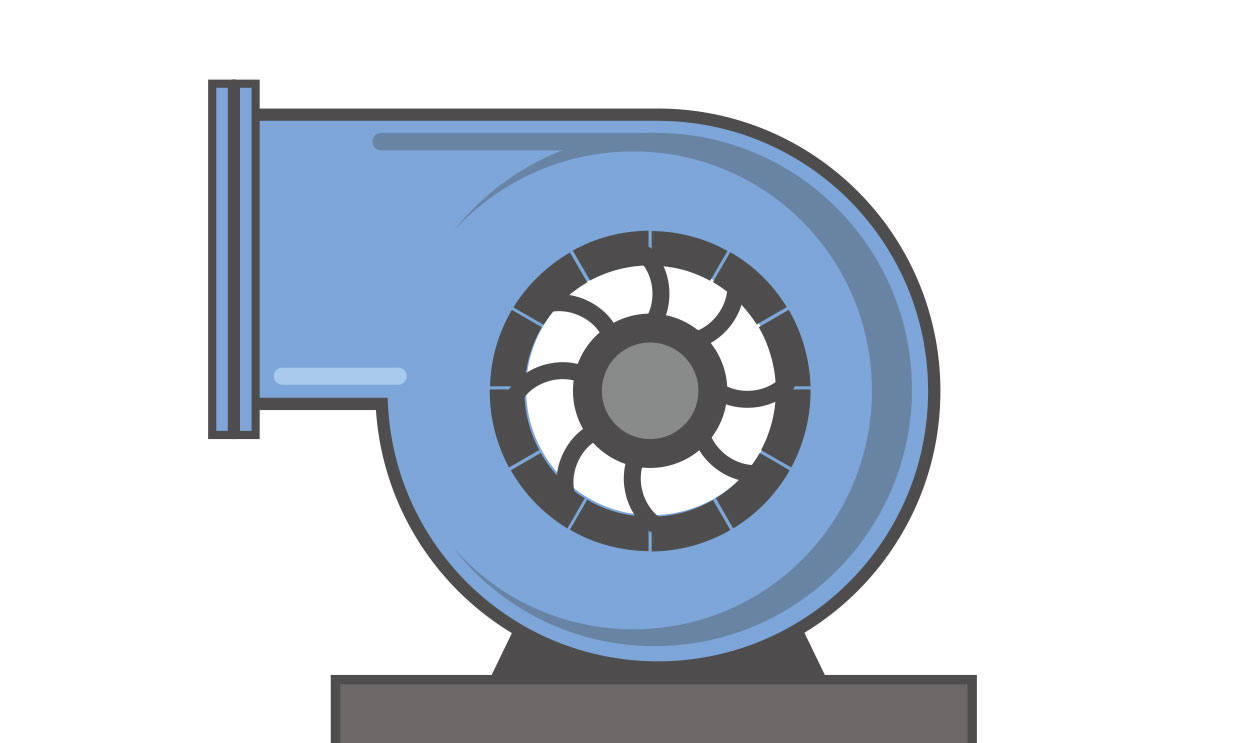

When discussing the anatomy of an industrial fan, one of the most critical yet often overlooked components is the fan housing, also known as the volute. Whether you're dealing with high-pressure ventilation, fume extraction, or dust control, the design of the fan housing plays a pivotal role in system performance.

The fan housing, or volute, is the outer casing that surrounds the impeller in a centrifugal fan. Its primary role is to capture and direct the air expelled from the rotating impeller and guide it toward the outlet efficiently.

Shaped like a spiral (similar to a snail shell or ammonite), the volute gradually increases in area from the point of air entry to the discharge point. This specific design allows it to harness the air's velocity and convert it into useful pressure.

The volute is not just a protective casing; it’s a precision-engineered aerodynamic structure that:

Its design also helps prevent recirculation and vibration, improving system stability and extending the fan’s lifespan.

In centrifugal fans, the volute is essential for directing air at a 90-degree angle away from the impeller’s axis. The controlled airflow path ensures that velocity pressure is converted into static pressure as smoothly as possible, maximising output.

Depending on your application, fan housings can be customised to:

At Fans and Blowers, we engineer volutes to meet the unique demands of each system, whether you're dealing with food processing, manufacturing, or heavy-duty industrial extraction.

Poorly designed or improperly installed housings can result in:

By working with experienced manufacturers, you ensure the volute is optimised for your fan's impeller, motor, and airflow needs.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance