News

13.01.2026

Industrial fans are critical for maintaining airflow in warehouses, factories, HVAC systems, and other industrial processes. When selecting the right fan, one of the key considerations is the drive type: belt-driven or direct-drive. Each system has unique advantages, and understanding the differences helps ensure optimal performance, efficiency, and maintenance planning.

Belt-driven fans use a belt and pulley system to transfer power from the motor to the fan impeller. The motor can be positioned remotely, allowing for flexible installation and speed adjustments through pulley sizing.

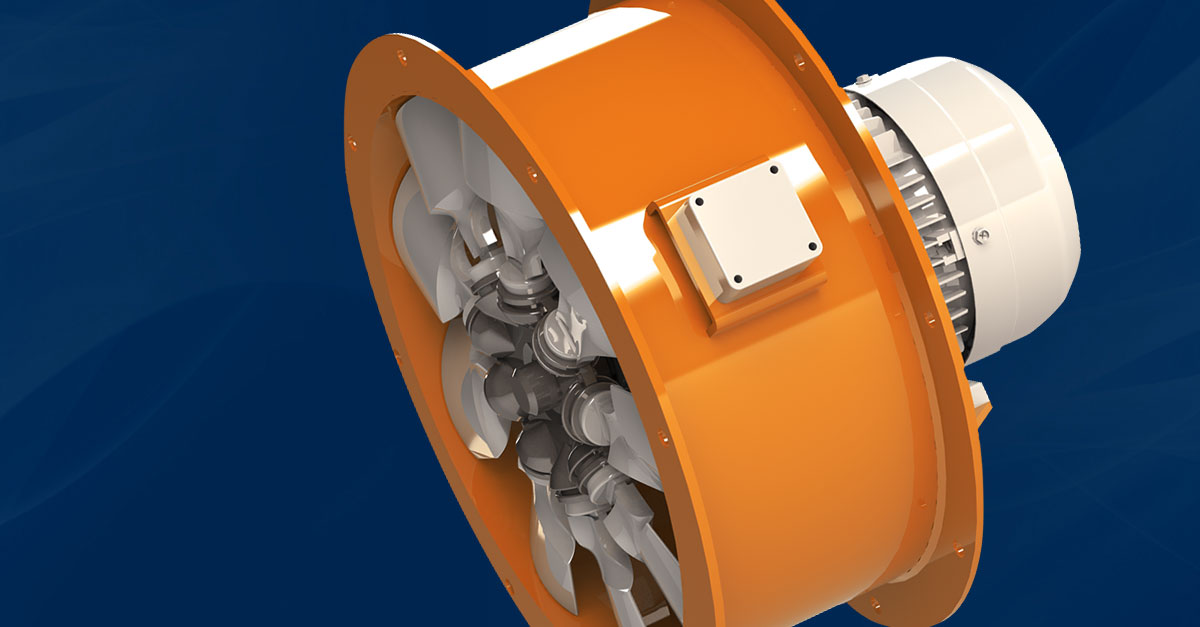

Direct-drive fans have the impeller mounted directly on the motor shaft, eliminating the need for belts and pulleys. This results in a simpler, more compact design.

| Feature | Belt-Driven Fans | Direct-Drive Fans |

| Maintenance | Requires belt checks and tension adjustments | Minimal maintenance, fewer moving parts |

| Energy Efficiency | Slightly lower due to belt friction | Higher efficiency with direct motor transfer |

| Installation Flexibility | Motor can be remote | Motor mounted directly on fan |

| Noise Levels | Slightly higher due to belt and pulleys | Quieter operation |

| Speed Adjustments | Easy via pulley changes | Limited – usually fixed motor speed |

| Applications | Large, high-torque, heavy-duty fans | Smaller, consistent-speed applications |

Both belt-driven and direct-drive industrial fans have advantages depending on your operational needs. Belt-driven fans offer flexibility and heavy-duty performance, while direct-drive fans provide higher efficiency, quieter operation, and lower maintenance. Selecting the right type ensures reliable airflow, energy efficiency, and long-term performance for your industrial processes.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance