Fan Impeller Guide | Centrifugal & Axial Fan Impellers

20.05.2025

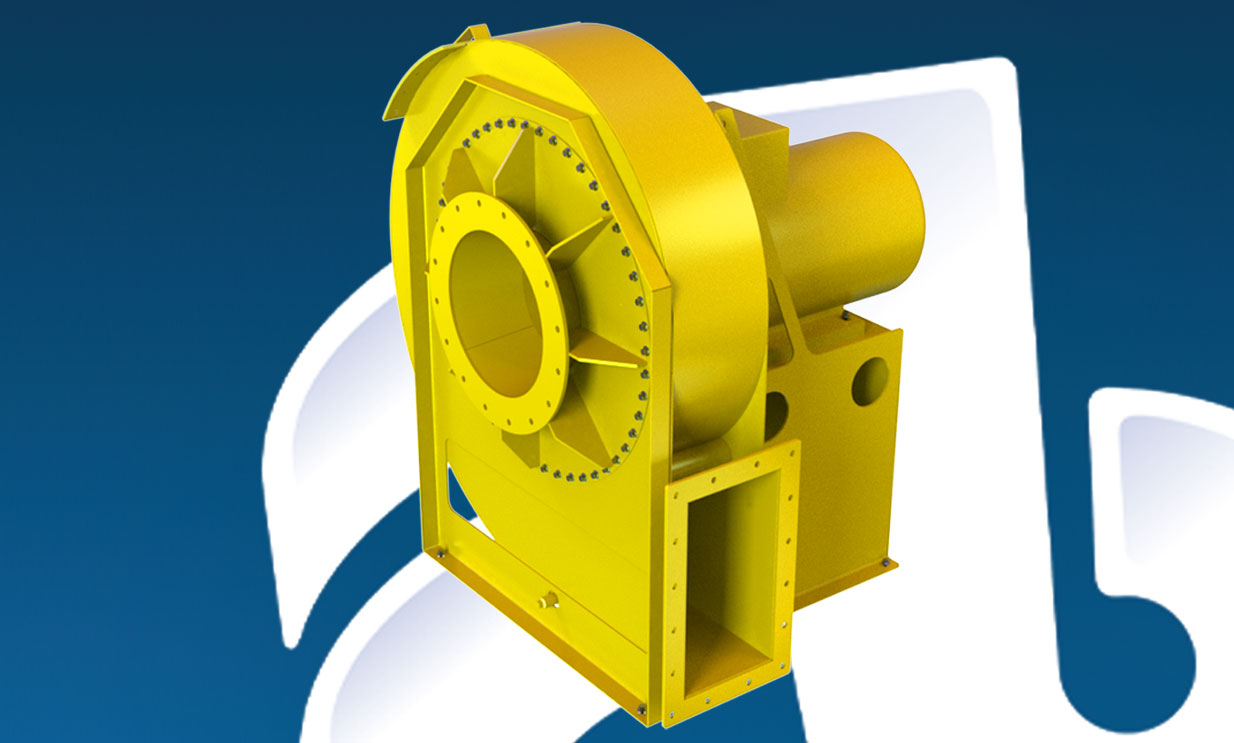

The fan impeller is the heart of every industrial fan, responsible for moving air efficiently, creating pressure, and delivering reliable airflow. Whether for ventilation, cooling, or process systems, understanding how a fan impeller works, the different types available, and their applications is key to selecting the right fan for your operation.

What Is a Fan Impeller?

A fan impeller is the rotating component of a fan that draws air into the system and pushes it outward. It typically consists of multiple blades arranged around a central hub. The impeller’s design directly influences:

- Airflow volume and velocity

- System pressure

- Noise levels

- Energy efficiency

Types of Impellers

There are different impeller designs to match specific industrial applications:

- Forward-curved blades – high-volume, low-pressure airflow. Ideal for gentle ventilation in ducted systems.

- Backward-curved blades – efficient and quieter, suited for medium-to-high pressure applications.

- Radial blades – robust, for handling particulates, moisture, or harsh industrial environments.

- Axial impellers – move air along the axis of rotation, perfect for high-volume, low-pressure tasks like large-space ventilation.

How a Fan Impeller Works

Centrifugal impellers draw air axially into the centre of the fan and expel it radially outward through the fan housing. This action generates a pressure difference that pushes air through ducts, filters, or resistant environments.

Key Steps:

- Air Intake: Air enters the impeller through the hub.

- Blade Rotation: Spinning blades create lift and centrifugal force.

- Air Acceleration: Air is flung outward, increasing velocity and pressure.

- Air Discharge: Air exits through the fan housing at the desired pressure.

Axial impellers push air parallel to the axis of rotation, allowing high-volume airflow with low pressure. These are ideal for:

Applications of Fan Impellers

Fan impellers are used in a wide range of industrial and commercial systems:

- HVAC & Air Handling Units – axial or backwards-curved centrifugal impellers for supply, extract, and recirculation.

- Dust & Fume Extraction – robust centrifugal impellers for ducted filtration systems.

- Spray Booth Extraction – impellers designed for airflow control and VOC removal.

- Boilers, Furnaces & Combustion Systems – high-pressure impellers for FD & ID fans.

- Industrial Cooling & Material Handling – impellers capable of handling dust, particles, or moisture.

Key Features of Quality Fan Impellers

When selecting or replacing an impeller, consider:

- Material: Aluminium, mild steel, stainless steel, or corrosion-resistant coatings for durability.

- Blade Design: Forward, backward, radial, or airfoil shapes to optimise airflow and noise.

- Balancing: Precision balancing for smooth operation and reduced vibration.

- Customisation: Tailored diameters, blade counts, and hub sizes to suit unique installations.

- Safety: ATEX-rated options for explosive or hazardous environments.

How to Control a Fan Impeller

Methods of Control

Fan impellers can be controlled to adjust airflow and pressure:

- Dampers: Manual or electrically operated flaps to restrict airflow.

- Variable Frequency Drives (VFDs): Control motor speed to regulate impeller rotation and airflow.

- System Design: Ensure proper back pressure to prevent impeller overspeed, particularly for backward-curved and paddle impellers.

Axial vs. Centrifugal Impellers

| Feature |

Axial Impeller |

Centrifugal Impeller |

| Airflow |

High-volume |

Medium to high |

| Pressure |

Low |

Medium to high |

| Direction |

Straight-line |

Radial |

| Applications |

Large-space ventilation, cooling |

Ducted systems, dust extraction |

| Noise |

Moderate |

Moderate to low (backward-curved) |

Why the Fan Impeller Matters

The impeller is the engine behind efficient air movement. A well-designed impeller improves:

- Airflow efficiency

- Energy consumption

- Noise control

- Fan lifespan

Choosing the right impeller for your system ensures reliability, safety, and optimal performance.

FAQs About Fan Impellers

Q1: What is the difference between an axial and centrifugal fan impeller?

A: Axial impellers move air along the axis for high-volume, low-pressure applications, while centrifugal impellers move air radially for higher-pressure systems.

Q2: Can a fan impeller handle dust and moisture?

A: Radial and backwards-curved impellers are designed for rugged conditions with particulates, moisture, and harsh industrial environments.

Q3: How do I know which impeller is right for my system?

A: Consider airflow volume, pressure requirements, environmental conditions, and motor compatibility. Expert guidance from a trusted manufacturer is recommended.

Q4: Can fan impellers be customised?

A: Yes. Custom diameters, blade designs, hub sizes, and materials are available for unique industrial applications.

Choose Fans and Blowers for Your Fan Impellers

At Fans and Blowers, we supply high-quality centrifugal and axial fan impellers engineered for:

- Industrial ventilation

- Dust and fume extraction

- Spray booth airflow

- HVAC systems

Our team can design, balance, and supply impellers to meet your exact requirements, ensuring maximum efficiency, reliability, and durability.

Contact us today to find the right fan impeller for your system.

Return To News