News

16.10.2025

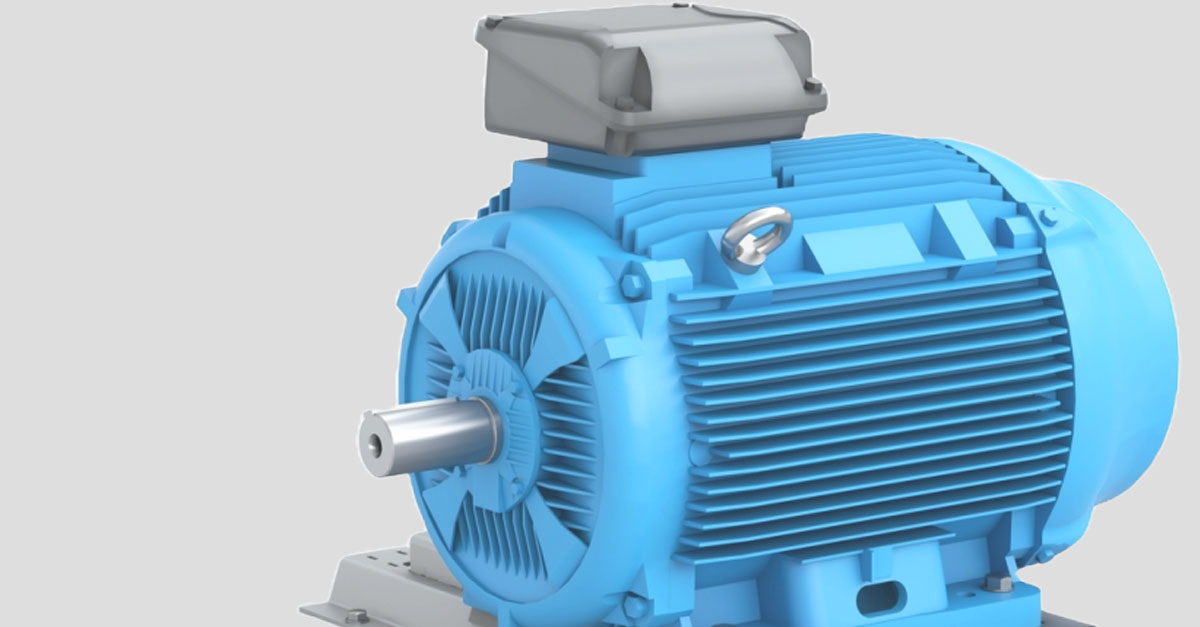

When selecting a motor for industrial, commercial, or ventilation applications, understanding performance, efficiency, and reliability is essential. The best motor is not necessarily the most expensive — it’s the one that meets your operational needs while offering durability, low maintenance, and energy efficiency.

Key factors include:

AC motors are widely used in industrial applications. They are reliable, easy to maintain, and available in various configurations such as squirrel-cage induction motors or synchronous motors. AC motors are ideal for fans, pumps, and general machinery.

DC motors provide precise speed control and are commonly used in applications requiring variable speed operation. They are ideal for equipment like conveyor systems and specialized machinery.

High-efficiency motors minimise energy consumption and comply with modern energy regulations. They are designed for continuous operation in industrial environments while reducing operating costs.

The best motor must withstand continuous operation in harsh conditions, including temperature fluctuations, dust, moisture, and vibration.

Motors with sealed bearings and robust construction reduce maintenance intervals and minimise downtime, ensuring long-term performance.

High-efficiency motors save energy and reduce costs, making them ideal for operations running 24/7.

Motors designed for smooth operation and minimal vibration contribute to quieter workplaces, which is especially important in commercial or indoor settings.

The best motor is one that combines efficiency, reliability, durability, and performance tailored to your specific application. By understanding the requirements of your system and considering motor type, efficiency, and maintenance, you can ensure long-term operational success while minimizing energy costs and downtime.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance