News

30.09.2025

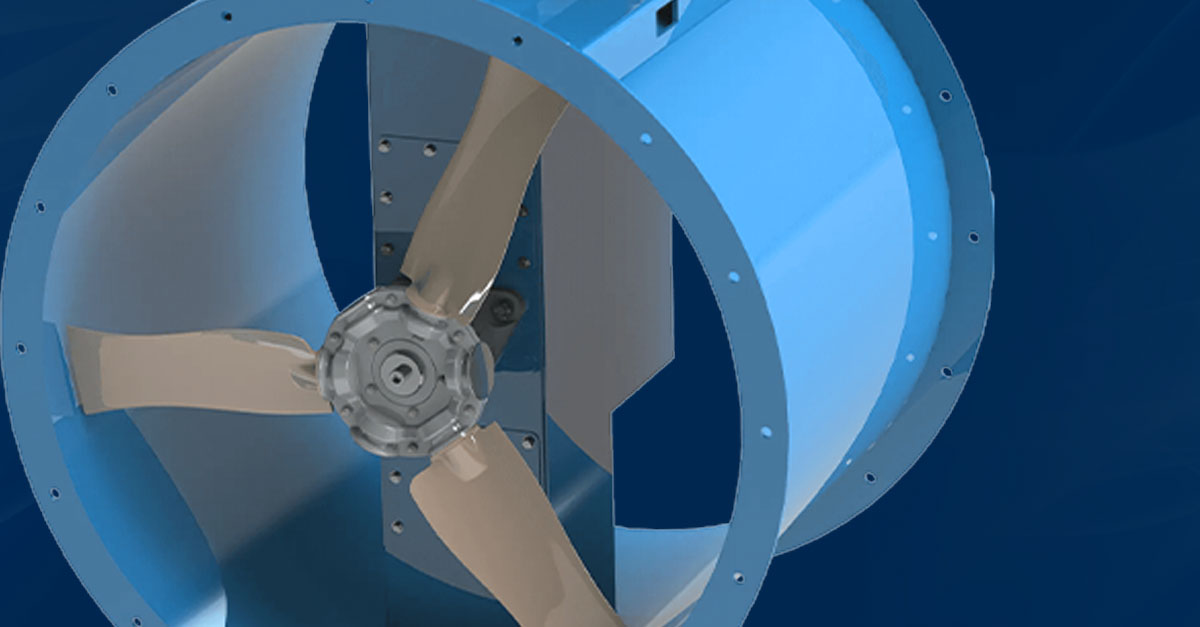

In industrial ventilation and air movement systems, axial fans are widely used for their high airflow and efficiency. At the heart of these fans is the axial impeller — the component responsible for generating airflow along the fan’s axis. Understanding what an axial impeller is and how it functions is essential for selecting, maintaining, and optimising your fan systems.

An axial impeller is a rotating component with blades mounted around a central hub. Unlike centrifugal fans, which move air outward radially, an axial impeller pushes air parallel to the axis of rotation. This design allows for high-volume, low-pressure airflow, making it ideal for cooling, ventilation, and industrial exhaust applications.

Axial impellers come in different designs, including:

Air enters the fan directly along its axis.

The impeller blades spin, generating lift and thrust that propel the air forward.

As air moves along the axis, it gains speed and is directed toward the fan outlet.

Air exits the fan at a consistent velocity, suitable for ventilation, cooling, or process airflow requirements.

This straightforward path of airflow makes axial impellers particularly effective for high-volume air movement over long distances with minimal pressure drop.

Axial impellers are used across a wide range of industries and applications:

Their ability to efficiently move air along the axis makes them indispensable in systems where high airflow at low pressure is required.

An axial impeller is the core component of an axial fan, responsible for generating straight-line airflow efficiently. Its design, whether fixed-pitch, variable-pitch, or airfoil-shaped, determines the fan’s performance, noise levels, and energy efficiency.

At Fans and Blowers, we supply high-quality axial impellers and fans tailored to industrial needs, ensuring reliable airflow, durability, and optimal performance for every application.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance