News

23.09.2025

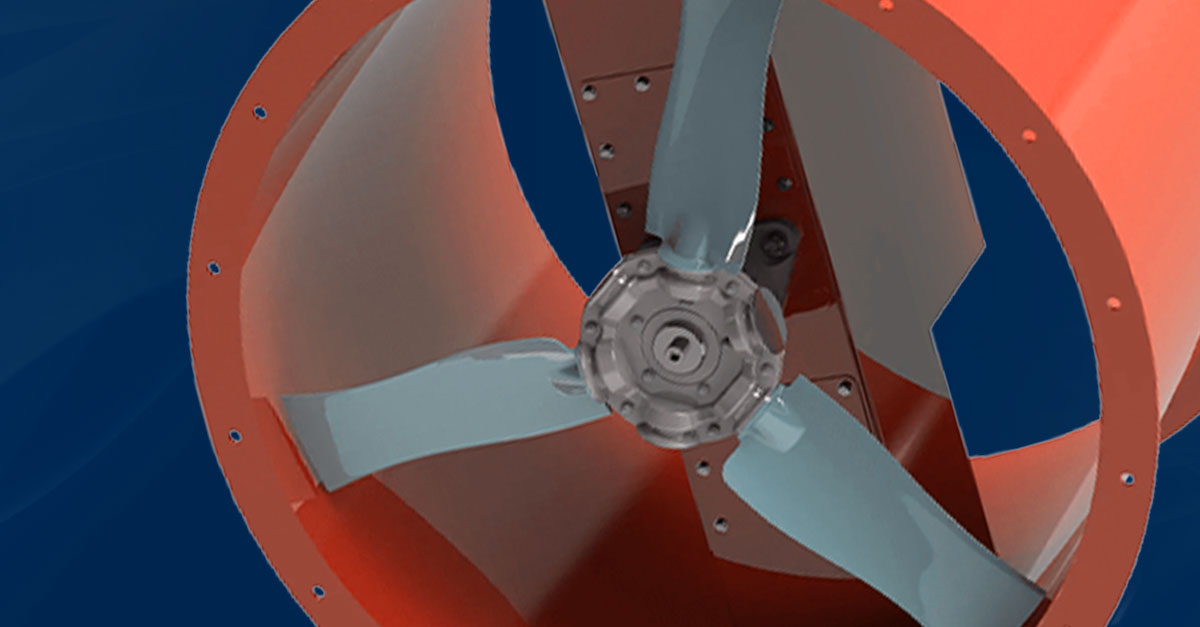

When it comes to moving air efficiently through a system, the impeller fan plays a crucial role. Whether used in centrifugal fans, industrial ventilation, or HVAC systems, the impeller is the component responsible for creating airflow and pressure. Understanding how an impeller fan works helps in selecting the right fan for your application and maintaining peak performance.

An impeller fan is a rotating component fitted with blades that transfer energy from the motor to the air. It sits at the centre of the fan housing, and as it spins, it converts mechanical energy into kinetic and pressure energy — effectively pushing or pulling air through the system.

There are several types of impellers, such as forward-curved, backward-curved, and radial designs. Each offers unique advantages depending on the required air volume, pressure, and noise levels.

Air enters the fan through the inlet at the centre of the impeller.

As the impeller rotates, the blades throw the air outward due to centrifugal force. This motion increases the air’s velocity and pressure.

The kinetic energy of the moving air is converted into static pressure within the fan housing (volute), directing the airflow toward the outlet.

The air exits the housing at a higher pressure and velocity, ready to perform tasks such as ventilation, drying, combustion air supply, or fume extraction.

In short, the impeller transforms rotational energy into controlled, directional airflow — making it the driving force behind most industrial and commercial fans.

The performance and efficiency of a fan depend heavily on impeller design.

Choosing the right impeller type ensures optimal airflow, energy efficiency, and durability.

Impeller fans are used across a wide range of industries, including:

Their versatility makes them indispensable in environments where controlled air movement is essential.

Understanding how an impeller fan works reveals just how vital this component is to air movement and system performance. From generating airflow to maintaining pressure stability, the impeller is the true powerhouse inside every fan.

At Fans and Blowers, we design and supply high-performance impeller fans tailored to your industrial needs — delivering efficiency, reliability, and long service life.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance