News

15.08.2023

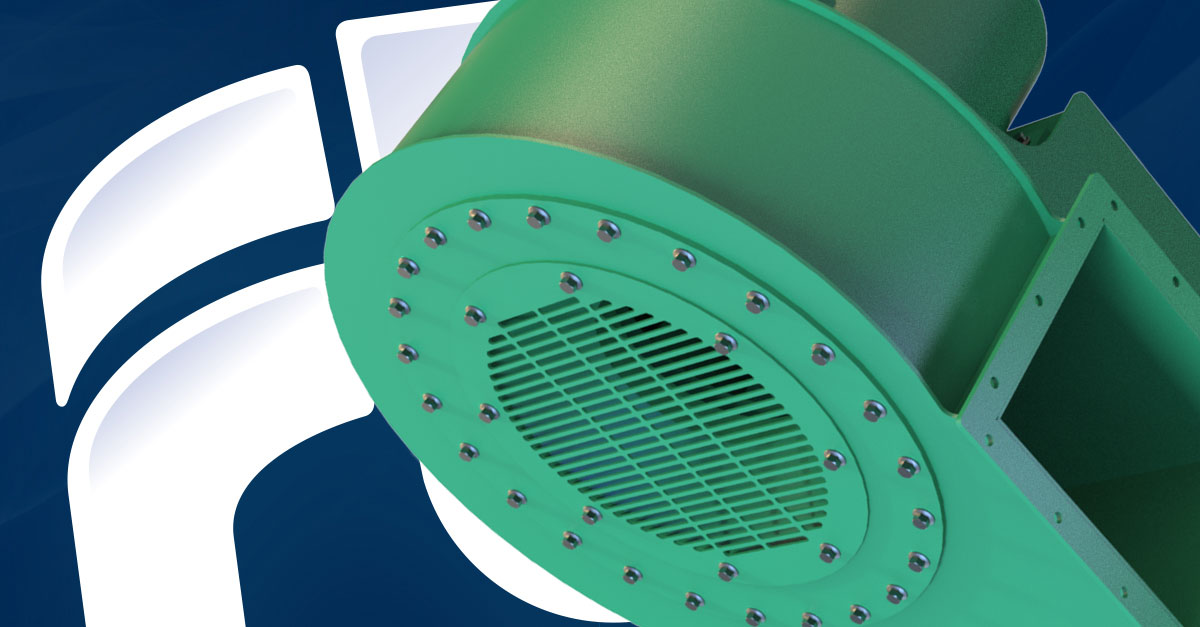

In various industrial and commercial applications, achieving efficient airflow is essential. Whether it's for ventilation, cooling, or pneumatic conveying, the right equipment can make all the difference. One crucial player in the world of airflow management is the centrifugal blower. In this blog, Fans and Blowers dive into the intricacies of centrifugal blowers, exploring their working principles, applications, and advantages.

A centrifugal blower, also known as a centrifugal fan, is a mechanical device designed to move air or other gases radially outward from the centre of rotation. Unlike axial fans that direct airflow parallel to the fan's axis, centrifugal blowers channel air at a right angle to the intake. This unique design creates a high-velocity airflow that is well-suited for applications that require both pressure and airflow, such as ventilation systems, air conditioning units, and industrial processes.

Centrifugal blowers operate based on a simple yet effective principle. When the blower's impeller, a rotating disc with blades, is set into motion, it creates a low-pressure area at the centre due to centrifugal force. As air is drawn into this low-pressure area from the surroundings, the spinning blades accelerate the air and fling it outward. The result is a high-velocity stream of air that exits the blower.

Centrifugal blowers find application across a wide range of industries and settings:

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, centrifugal blowers help circulate air through ducts, facilitating efficient temperature control and air distribution in buildings.

Industrial Processes: Industries like manufacturing, chemical, and pharmaceutical utilize centrifugal blowers for processes such as drying, cooling, and exhaust ventilation.

Power Generation: Centrifugal blowers play a role in cooling critical components of power generation systems, including turbines and generators.

Agriculture: In agriculture, these blowers aid in grain drying and maintaining optimal conditions in livestock facilities.

Pneumatic Conveying: They are used in pneumatic conveying systems to transport materials through pipelines using air pressure.

Material Handling: Industries dealing with bulk materials, such as cement and mining, use centrifugal blowers for efficient material handling and processing.

Higher Pressure Output: Centrifugal blowers are known for generating higher pressure compared to axial fans, making them suitable for applications that require both airflow and pressure.

Compact Design: Their compact form factor allows centrifugal blowers to fit into tight spaces, making them a preferred choice for applications with limited room.

Efficiency: These blowers are generally more efficient in producing airflow against resistance, ensuring efficient energy usage.

Less Sensitive to System Changes: Centrifugal blowers are less affected by changes in system resistance compared to axial fans, making them more adaptable to varying operating conditions.

Reduced Noise: The design of centrifugal blowers often results in lower noise levels, making them suitable for environments where noise is a concern.

In conclusion, centrifugal blowers are essential components in various industries, ensuring optimal airflow, temperature control, and material handling. Their unique design and efficient operation make them indispensable for applications requiring a balance between airflow and pressure. Whether it's keeping industrial processes running smoothly or maintaining comfortable indoor environments, Fans and Blowers' centrifugal specialists are at the forefront of efficient airflow management!

Click here to view our Centrifugal Blower Products

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance