News

22.04.2025

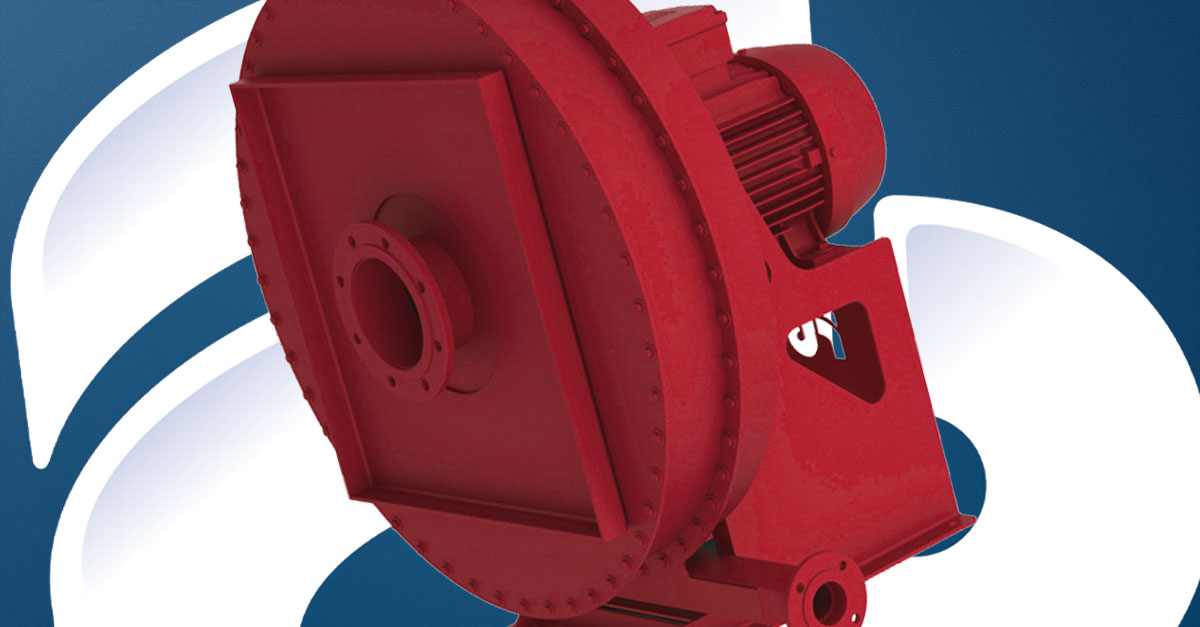

Centrifugal fans are a vital component in industrial ventilation systems, designed to move air or gases efficiently by converting rotational energy into airflow. Unlike axial fans, which push air along the axis of the fan, centrifugal fans use a rotating impeller to draw air into the centre and then expel it at a 90-degree angle through centrifugal force.

Centrifugal fans consist of several key components:

As the impeller spins, it pulls air into the fan's centre and then flings it outward by centrifugal force. The design allows for higher pressure development than axial fans, making them suitable for applications requiring air to travel through ductwork, filters, or resistance-heavy environments.

Centrifugal fans come in several blade configurations, each suited for different needs:

Centrifugal fans are widely used across industries for:

Learn about other uses for this fan by clicking here!

Centrifugal fans are ideal for environments where airflow must overcome resistance from filters, long duct runs, or equipment. Their adaptability and reliability make them a go-to solution for many industrial and commercial ventilation challenges.

Understanding what centrifugal fans are—and how they differ from other types—is essential when designing an effective air movement system. Whether you're planning a ventilation upgrade or need a reliable fan for industrial use, centrifugal fans offer durability, control, and performance you can trust.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance