News

13.05.2025

If you’re designing or upgrading an industrial ventilation system, one of the most important components is the fan. But how does a centrifugal fan work, and why is it preferred in many high-resistance air movement applications?

In this guide, we break down the core principles, components, and benefits of centrifugal fans—and why they are the top choice for many industrial and commercial settings.

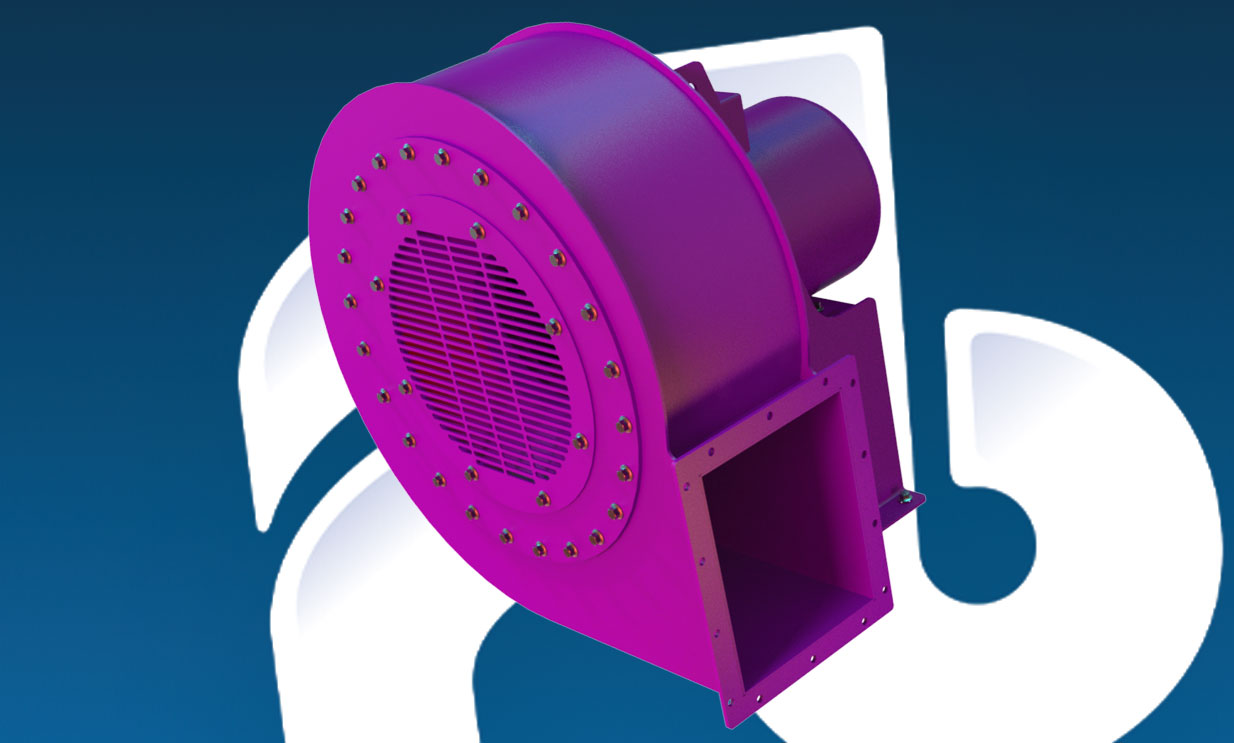

A centrifugal fan is a mechanical device that moves air or gases using centrifugal force. Air enters through the centre of the fan and is flung outward by a spinning impeller. This motion increases air pressure and redirects airflow at a 90-degree angle, making centrifugal fans ideal for ducted systems and resistance-heavy environments.

Let’s walk through how a centrifugal fan works step-by-step:

Unlike axial fans—which move air in a straight line—centrifugal fans change the direction of airflow, allowing them to overcome greater resistance in ductwork or filtration systems.

Understanding how a centrifugal fan works means looking at its parts:

Centrifugal fans are widely used in:

Any application requiring reliable airflow through ductwork or equipment will benefit from centrifugal fans. Find out more uses here!

Understanding how a centrifugal fan works is key to designing an efficient air movement system. These fans deliver consistent pressure, reliable airflow, and versatile performance across a wide range of industrial applications.

At Fans and Blowers, we supply and design centrifugal fans that meet your specific performance needs—whether off-the-shelf or fully bespoke.

Need help choosing the right fan? Our team is here to help. Contact us for custom advice, specs, and a free quote.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance