News

27.05.2025

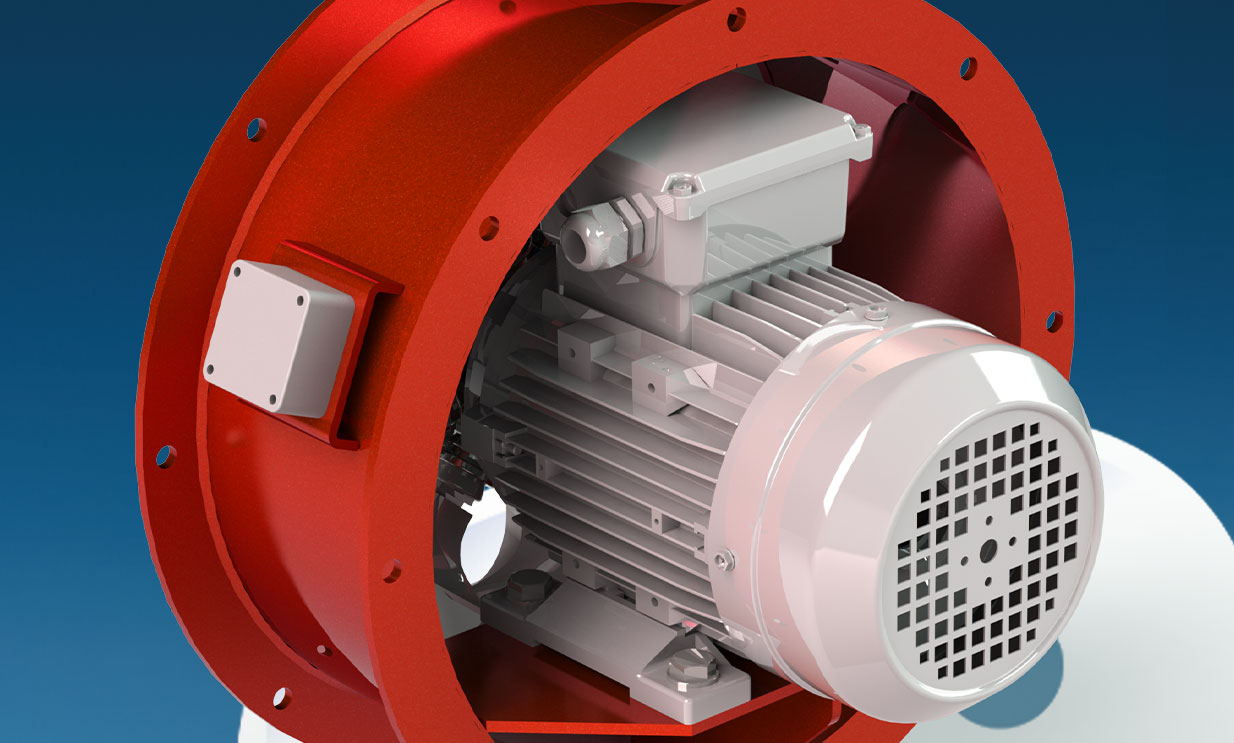

When it comes to industrial fans, the fan motor is the heart of the system. It’s the component that powers the impeller, generating the movement needed to create effective airflow. Whether you're looking to ventilate a factory, extract fumes, or cool equipment, the right motor selection is key to efficiency and performance.

A fan motor is an electric device that converts electrical energy into mechanical energy to spin the fan’s impeller. It directly influences how fast the impeller rotates, how much air is moved, and how efficiently the fan runs.

Fan motors are typically:

There are two primary drive types in industrial fan systems:

In this setup, the motor shaft is directly connected to the impeller. This means:

Here, a belt and pulley system connects the motor to the impeller. Benefits include:

The number of motor poles and the frequency of the power supply both impact impeller speed (RPM):

These values change with 60 Hz systems (common in North America), allowing for higher rotational speeds. The right match ensures optimal airflow and energy use.

At Fans and Blowers, we supply and design motors for harsh, demanding environments. Our fan motors are:

Whether you're dealing with corrosive fumes, high ambient temperatures, or explosive particles, we can specify a motor to handle it.

A poorly matched or underpowered motor can lead to:

By partnering with experienced fan motor manufacturers, you can rest assured that your system is both reliable and efficient.

Return To NewsKeep up to date with our

Our Range

Worldwide shipping

International standards

High performance