News

Inlet & Outlet Fan Design | Improve Airflow and Efficiency

03.06.2025

When it comes to fan performance, most of the attention goes to the impeller or motor. However, the fan inlet and outlet are equally critical. Their design, positioning, and treatment have a major impact on airflow efficiency, pressure, and noise levels.

At Fans and Blowers, we engineer complete ventilation solutions, and that means optimising not just the fan itself, but how air enters and exits the system. In this blog, we explore the importance of fan inlet and outlet design, how it affects overall performance, and what to consider during selection or installation.

What Is a Fan Inlet?

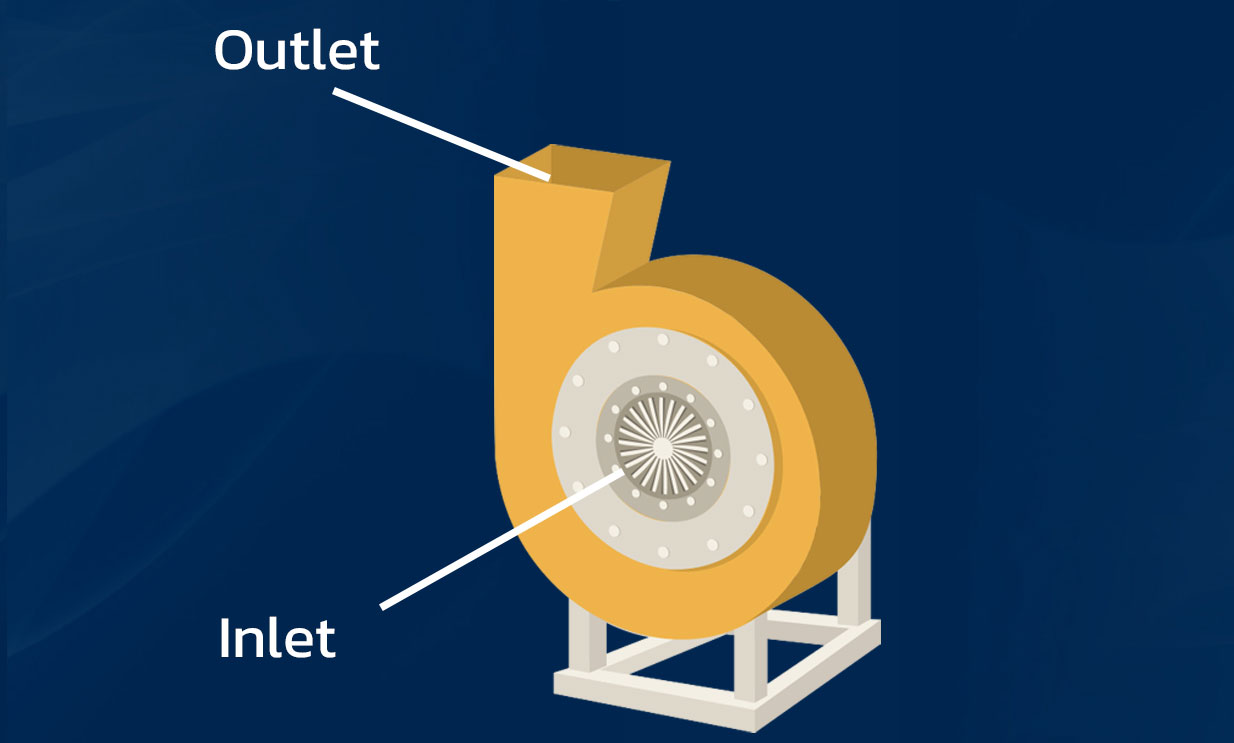

The fan inlet is the opening through which air enters the fan. Whether on an axial or centrifugal fan, the inlet design determines how smoothly air is guided into the impeller.

Key Design Features:

- Bellmouth inlets: These provide a smooth transition for airflow, reducing turbulence and improving efficiency.

- Straight vs. tapered entries: A tapered inlet can accelerate air more gradually, leading to quieter operation.

- Inlet box/plenum: Used in centrifugal fans to ensure even air distribution across the impeller face.

Why It Matters:

- Poor inlet conditions can lead to airflow separation, turbulence, and reduced pressure performance.

- Inlet restrictions or sharp turns cause uneven loading on the impeller, increasing noise and wear.

What Is a Fan Outlet?

The fan outlet is where air exits the fan and enters the connected ductwork or application space. The outlet shape and configuration affect the fan’s ability to maintain pressure and direct airflow efficiently.

Outlet Types:

- Rectangular or circular outlets: Depends on ducting requirements

- Diffuser outlets: Used to gradually reduce air velocity and regain static pressure

- Outlet dampers: Help regulate flow and pressure in real time

Outlet Effects on Performance:

- A poorly designed outlet can cause back pressure, reducing the fan’s efficiency and increasing energy consumption.

- Obstructions near the outlet can generate turbulence, noise, and mechanical stress on the fan.

Matching Inlet & Outlet for System Efficiency

For optimal system performance, the fan’s inlet and outlet must be integrated into the overall ductwork or ventilation layout. This includes:

- Clear, straight duct runs before and after the fan

- Proper transitions to match duct size and shape with minimal disruption

- Flexible connectors to reduce vibration and noise transmission

At Fans and Blowers, we ensure that the fan’s inlet and outlet geometry is fully compatible with its intended application, whether that's HVAC, process ventilation, fume extraction, or industrial cooling.

Inlet & Outlet Accessories Available

To support performance and installation, we offer a full range of fan inlet and outlet accessories, including:

- Bellmouth inlets

- Inlet boxes and dampers

- Discharge diffusers

- Flexible connectors

- Transition pieces and flanges

All components are available in a range of materials, including mild steel, stainless steel, aluminium, and coated finishes for corrosion resistance.

Inlets and outlets of a fan

The inlet and outlet of a fan are not just entry and exit points—they’re crucial performance zones that directly affect airflow, efficiency, and noise. A well-designed system considers these elements from the start to avoid costly losses in energy and reliability.

Fans and Blowers provides expert advice and tailored fan solutions, ensuring that every detail, right down to the inlet and outlet, is optimised for your application.

Need help selecting the right fan configuration?

Contact our team or explore our full range of axial and centrifugal fans with matching inlet and outlet accessories.

Return To NewsPRODUCTS WITH EXCEPTIONAL PERFORMANCE

Our Range