News

How Does a Centrifugal Fan Work? | Guide Explained Simply

13.05.2025

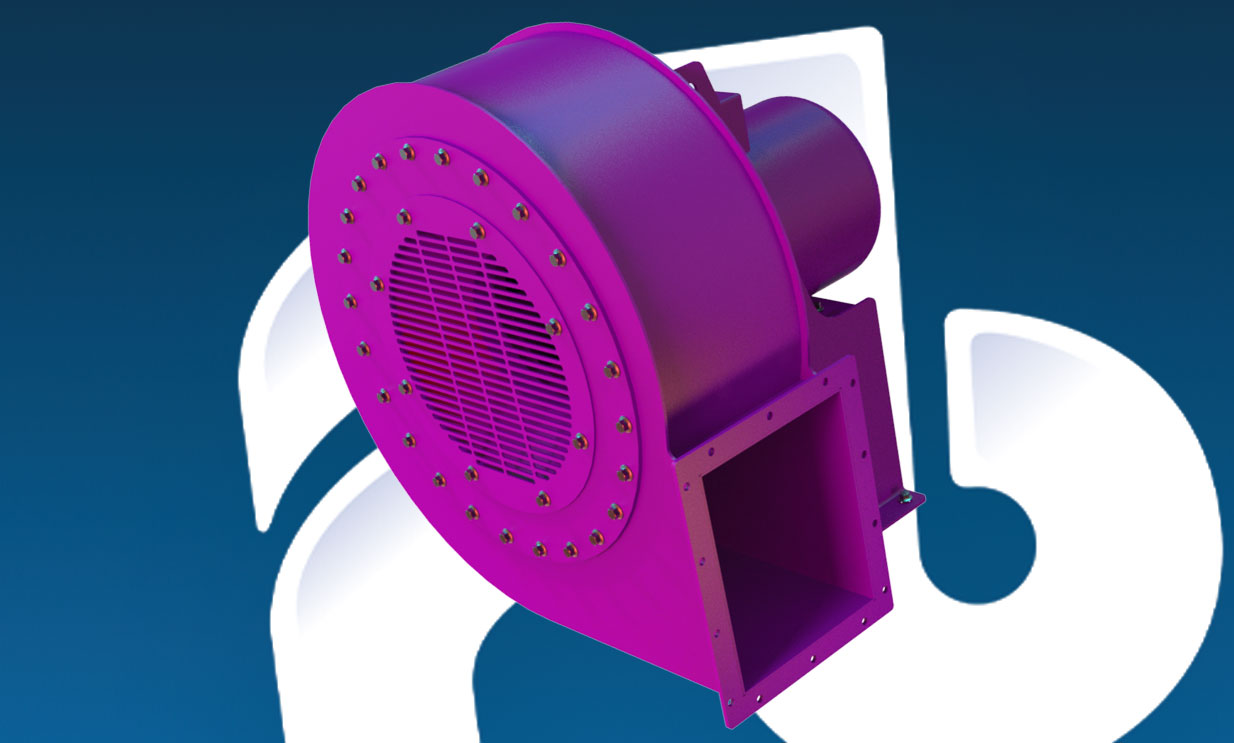

If you’re designing or upgrading an industrial ventilation system, one of the most important components is the fan. But how does a centrifugal fan work, and why is it preferred in many high-resistance air movement applications?

In this guide, we break down the core principles, components, and benefits of centrifugal fans—and why they are the top choice for many industrial and commercial settings.

What Is a Centrifugal Fan?

A centrifugal fan is a mechanical device that moves air or gases using centrifugal force. Air enters through the centre of the fan and is flung outward by a spinning impeller. This motion increases air pressure and redirects airflow at a 90-degree angle, making centrifugal fans ideal for ducted systems and resistance-heavy environments.

How Does a Centrifugal Fan Work?

Let’s walk through how a centrifugal fan works step-by-step:

- Air enters the fan via a central inlet.

- The impeller rotates, creating centrifugal force.

- Air is pushed outward from the impeller’s center to the edge.

- The housing directs the air out through the discharge port at a higher pressure and velocity.

Unlike axial fans—which move air in a straight line—centrifugal fans change the direction of airflow, allowing them to overcome greater resistance in ductwork or filtration systems.

Key Components in a Centrifugal Fan

Understanding how a centrifugal fan works means looking at its parts:

- Impeller: The rotating blade assembly that generates centrifugal force. Blade shapes (forward-curved, backward-curved, radial) affect airflow and pressure.

- Fan Housing (Volute): A spiral-shaped casing that channels and compresses air, increasing pressure before discharge.

- Motor: Powers the impeller. Available in direct-drive or belt-drive configurations.

- Inlet & Outlet: Air enters through the center and exits perpendicular to the intake.

Advantages of Using Centrifugal Fans

- High Static Pressure: Ideal for ducted systems or where airflow must overcome filters or resistance.

- Direction Control: Redirects airflow by 90°, ideal for compact or complex layouts.

- Quieter Operation: Especially backwards-curved fans in closed systems.

- Durable Design: Handles corrosive, dusty, or high-moisture environments.

- Energy Efficient: Engineered for consistent, reliable performance with minimal waste.

Common Applications of Centrifugal Fans

Centrifugal fans are widely used in:

- HVAC systems

- Dust and fume extraction

- Spray booths

- Drying systems

- Pharmaceutical & cleanroom exhausts

- Industrial process ventilation

Any application requiring reliable airflow through ductwork or equipment will benefit from centrifugal fans. Find out more uses here!

Why You Should Use a Centrifugal Fan

Understanding how a centrifugal fan works is key to designing an efficient air movement system. These fans deliver consistent pressure, reliable airflow, and versatile performance across a wide range of industrial applications.

At Fans and Blowers, we supply and design centrifugal fans that meet your specific performance needs—whether off-the-shelf or fully bespoke.

Talk to Our Experts

Need help choosing the right fan? Our team is here to help. Contact us for custom advice, specs, and a free quote.

Return To NewsKeep up to date with our

Latest News

-

Fans & Blowers Acquires B.O.B. Stevenson | Announcement

View more -

How Is the Centrifugal Blower Turned? Drive Types Explained

View more -

Types of Centrifugal Fans Explained | Industrial Fan Guide

View more -

Industrial Cooling Fans: How they work, Uses and Benefits

View more -

What is a Rotating Shaft on a fan? Applications and Benefits

View more -

Quiet Axial Fans | Low-Noise Industrial Fans with Silencers

View more -

Inlet & Outlet Fan Design | Improve Airflow and Efficiency

View more -

Expert Air Control Solution | Fans Built for Controlling Air

View more -

Fan Motors for Industrial Fans | Direct & Belt Drive Options

View more -

Fan Housing (Volute) Explained | Centrifugal Fan Efficiency

View more -

Fan Impeller Guide | Centrifugal Fan Impeller & Manufacturer

View more -

Compressed Air Safety with Industrial Fans and Blowers

View more -

How Does a Centrifugal Fan Work? | Guide Explained Simply

View more -

What Are Axial Flow Fans? | Industrial Ventilation Explained

View more -

Are Centrifugal Fans Quieter? | Noise Comparison & Benefits

View more -

What Are Centrifugal Fans? | Industrial Fans & Blowers Guide

View more -

What is HVAC? Understanding what HVAC stands for

View more -

How Does an Axial Fan Work? | Learn About Their Functions

View more -

What is ATEX? ATEX Equipment and Explosive Atmospheres

View more -

New Job Vacancy: Welder/Fabricator – Join Our F&B Team!

View more -

Fans and Blowers partner with FBG Servicing for expert industrial fan servicing

View more -

Celebrating National Engineers Week at Fans and Blowers

View more -

Fans & Blowers Introduce Side Channel Blowers to the roster!

View more -

Josh Roddick joins the team as F&B Production Manager!

View more -

A Christmas Message from All of Us at Fans and Blowers

View more -

Fans and Blowers Achieves Recertification ISO 14001 ISO 9001

View more -

Fans and Blowers for Air Knife Systems: Powerful Solutions

View more -

Everything You Need to Know About Axial HVAC Fans

View more -

Silencers for Fans: Reduce your Industrial Noise Levels

View more -

Inlet Filters: Maintain Clean Airflow and Protect Equipment

View more -

New Fans and Blowers Shop Now Live

View more -

Meet Fans and Blowers’ New Apprentice: Finley Huggins!

View more -

ATEX Explosion Proof Fan: Safety in Hazardous Environments

View more -

Discover Our Latest Product: Multivane Forward Curved Fans

View more -

How to Make an Industrial Fan Quiet: Tips and Techniques

View more -

What’s the Difference Between a Radial Fan vs Axial fan

View more -

Learning the importance of Fans & Blowers Industrial Blowers

View more -

Unlocking Reliability and Effectiveness with Bifurcated Fans

View more -

Ensuring Efficiency: The Value of Dust & Fume Extraction

View more -

Exploring the Functions of Gas Booster and Exhauster Fans

View more -

Unleashing the Potential of Axial Fans: Endless Applications

View more -

What are Axial Fans used for?

View more -

Our Fume Extract Fans are Clearing the Air of Hazardous Fumes

View more -

Unveiling ATEX Fans’ Vital Role in Hazardous Environments

View more -

How much electricity does an industrial fan use?

View more -

What is a Centrifugal Blower?

View more -

What is an Axial Fan?

View more -

What is a Centrifugal Fan used for?

View more -

New Vacancy: Welder/Fabricator

View more -

Axial Fans vs Centrifugal Fans

View more -

The advantages of Axial Fans

View more -

Industries that our industrial Fans and Blowers excel in

View more -

Celebrating 50 years of manufacturing

View more -

Introducing a world leading axial fan range

View more -

Centrifugal specialists

View more -

Laser cutting services

View more -

New digital media for 2022

View more -

On-site service and maintenance

View more -

On-site nitrogen production plant

View more -

Meet our new engineering Graduate

View more -

New factory signage

View more -

A fresh new look for our website

View more -

Duncan Celebrates 25 Years at Fans and Blowers

View more -

Weatherproof Acoustic Enclosure to meet noise restrictions

View more -

Fresh Look for the Flat Bed

View more -

BSZ Fans On Their Way To Europe

View more

PRODUCTS WITH EXCEPTIONAL PERFORMANCE

Our Range

Shop Fans

Shop our range of Multi-Vane FansWorldwide shipping

International standards

High performance